Important Context

For some of these questions, the answer might appear to be obvious. Evaluating the production capacity of a build-to-print manufacturer becomes irrelevant once a lead time is quoted. But, in this example, quoting a lead time for complex drawings and equipment requires your engagement with a manufacturer. Determining a lead time will take several days, if not weeks, to determine. These questions will help you evaluate potential manufacturing partners to create an initial prequalification list.

Evaluating Build-to-Print Manufacturers by Topic

Can the Build-To-Print Manufacturer Meet Required Production Schedules?

The first thing to do is assess the manufacturer’s production capacity. Start by looking at the numbers. How many employees do the potential partners have? Having that question answered can give you insight into their total capacity. Knowing the total number of employees is important, but zeroing in on the number of laborers, fabricators, and machinists is a better indicator of production capacity.

In addition to personnel, research the in-house manufacturing equipment utilized by potential partners. On many websites in technical literature, companies will list their equipment and its capacity. This list might include general equipment like weld positioners and plate rollers, investment in automated welding equipment such as a robotic welding arm, or the x, y, and z travel dimensions of a horizontal boring mill.

Certainly, manufacturing companies leverage outsourced partners when necessary to complete a project. But, a lack of in-house equipment required for your build-to-print project could add time to the production schedule that would hurt your production schedule.

Evaluate Similar Project Experience

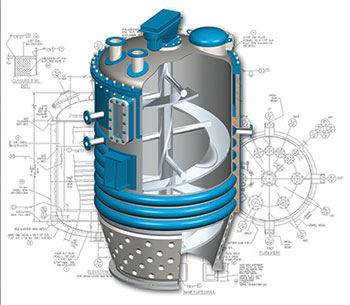

Once you have assessed the capacity of the manufacturer, it’s important to evaluate their project history. Look for information about their experience producing products similar to yours. Media galleries, project case studies, and industry-specific web pages are great places to look for demonstrated project experience.

Along with project data, look for certifications and procedures related to your project. For many, ASME certifications and vessel stamps (R, U, etc.) are obviously essential for built-to-print projects including pressurized vessels. The sheer number and types of certified weld procedures a company owns will give you the confidence to find a partner that has verifiable experience with your procedures.

What are Qualified Weld Procedures?

Qualified weld procedures are specific instructions that are followed during the welding process to ensure consistency in the final product. These procedures include details on the type of welding equipment to be used, the materials to be welded, and the welding technique to be applied.

Because qualified weld procedures are documented and tested to adhere to necessary quality standards, they can also help prevent welding defects, such as cracking, and ensure that the welds are strong enough to withstand the intended use.

The second aspect of having qualified weld procedures is having welders who have demonstrated the skills required to become certified. The number of welders certified for the qualified weld procedures required for your project is another indicator of manufacturing capacity to be analyzed. Having certified weld procedures is especially important for critical applications common in nuclear, chemical, or oil and gas industries.

Hassle-Free Considerations for Value-Add Services?

When searching for built-to-print manufacturers, value-add ancillary services are often overlooked. Convention causes many buyers to think of their search for suppliers only through the lens of what manufacturing service can be provided. This line of thinking could result in buyers having to handle a lot of the logistics around the service themselves. Some examples of these value-add services include manufacturability, project management, shipping, and logistics.

ASME Pressure Vessels on R-V Trucks

Manufacturability

By definition, manufacturability refers to the ease with which a product or design can be manufactured efficiently and effectively at a reasonable cost. It is a measure of how well a piece of equipment can be produced using existing manufacturing processes, equipment, and materials. Achieving optimal manufacturability does not guarantee lowest cost. It does ensure that the prints will be produced at the intersection of quality and cost-effectiveness.

Properly leveraging manufacturability with your design requires conversation. It is essential to find an expert manufacturer that has the custom engineering and design experience to point out opportunities for design improvement. With proper design suggestions and improvements, you could experience efficiency and lower costs driven by a reduction in manufacturing (pre-fabrication, welding, machining, etc.) hours.

Project Management

This appears basic. Surely, most companies encounter will talk about their experience in managing large projects. Many will mention the tools they use. Both are important topics. But, a good project management barometer for identifying ideal partners should be focused on 2 things: dedicated project management staff and their nearness to the manufacturing process.

When working with dedicated project management staff, you’ll receive consistent communication and the clarity that comes with a single point of contact. You also have a higher degree of flexibility over the project. For custom projects, scope changes are not an infrequent occurrence during the manufacturing process. Getting up-to-the-hour updates on the process to explore the feasibility and cost of project adders is a significant benefit. This is done best by dedicated project management staff.

Even though the prevalence of remote management has exploded in recent years, the proximity of project management staff to the manufacturing team improves the quality and frequency of updates. For mission-critical projects with tight lead times, we’ve provided updates in as little as 15 minutes from client requests. This is significantly easier when built-to-print manufacturers have teams in close proximity to each other.

Empowered to Choose Your Next Built-to-Print Partner

Selecting a built-to-print manufacturing partner can be a daunting process, but it doesn’t have to be. By considering factors such as production capacity, project experience, certified weld procedures, and value-add services like manufacturability and project management, you can prequalify potential manufacturing partners and make an informed decision that aligns with your project goals and timeline. Using these talking points to ask the necessary questions will help find the perfect intersection of quality and cost-effectiveness in your search for a supplier.

Contact us to ask additional questions about what we offer as a build-to-print manufacturer.